���b���Tʽ���ؙC(j��) MU���Tʽ���ؙC(j��) ؛��(ch��ng)���ؙC(j��) �bж�����ؙC(j��) Container gantry crane MU type gantry crane yard crane loading and unloading bridge crane

���b���Tʽ���ؙC(j��)MU���Tʽ���ؙC(j��)

MJ��܉�E���b���Tʽ���ؙC(j��) ɽ�|���x���ؙC(j��)е����˾ MJ type track container gantry crane Shandong Longhui Crane Machinery CO.,LTD ��˾�Ⱥ�ͨ�^(gu��)�ˡ�ISO9001�����|(zh��)���k���wϵ�����������ISO14001�h(hu��n)���k���wϵ������GB/T28001���I(y��)������ȫ�k���wϵ�����J(r��n)�C��������@���ˡ���

�M(j��n)��˾���������\(ch��ng)����˾�����������|(zh��)���k�����M(j��n)��˾������ȫ��(gu��)���M(f��i)���ŵ��^(gu��)��˾����������ȫ��(gu��)���M(f��i)���ŵ��^(gu��)��Ʒ�������Z��AAA��(j��)��˾�����������|(zh��)���^(gu��)Ӳ����

Ʒ�ƹ�˾����������Ʒ�����������Ƽ���˾�����S���s�u(y��)���ǬF(xi��n)�ڇ�(gu��)��(n��i)�I(y��)�H�߃r(ji��)ֵ���������ε���Ʒ֮һ��� Our company brand has been much valued and most trusted for we passed and got such honors: ��ISO9001 world quality handling system���� ��ISO14001 environment handing system���������GB/T28001 working health and safety handing system�������Advanced Company��, ��Honesty and Law Abiding Company��, ��Quality Handing Advanced Company��, ��National Consumer Trusted Company��, ��National Consumer Trusted Products��, ��Promise AAA Level Company��, ��Excellent Quality Brand Company��, ��Well known Products��, ��High-tech Company��, etc. ܉�Eʽ���b�����T���ؙC(j��)����

�º�(ji��n)�Q܉�E�������Ї�(gu��)���b��ۿڵ��bж���I(y��)�У�ͨ���x�ð�߅���b�����ؙC(j��)��݆̥ʽ���b�����T���ؙC(j��)�����º�(ji��n)�Q݆̥�������bжӋ(j��)��������݆̥������ш�(ch��ng)��

��Ҫ�bж�C(j��)е����ڇ�(gu��)��(n��i)��܉�E���H��һЩ؛��(ch��ng)������(y��ng)������@Щ܉�E�������I(y��)�ȼ�(j��)��늿��wϵ����k���wϵ�ȷ����h(yu��n)�h(yu��n)����ڬF(xi��n)�еĸۿڙC(j��)еˮƽ�����ܝM��F(xi��n)���ۿڼ�

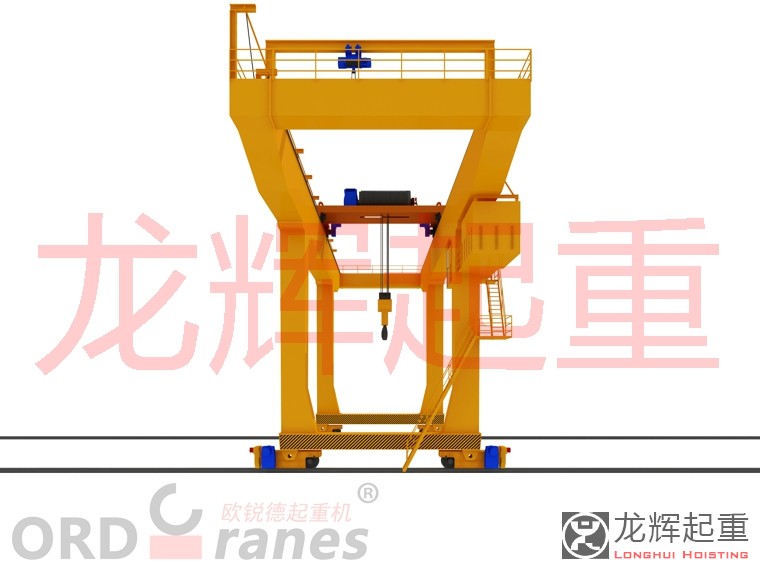

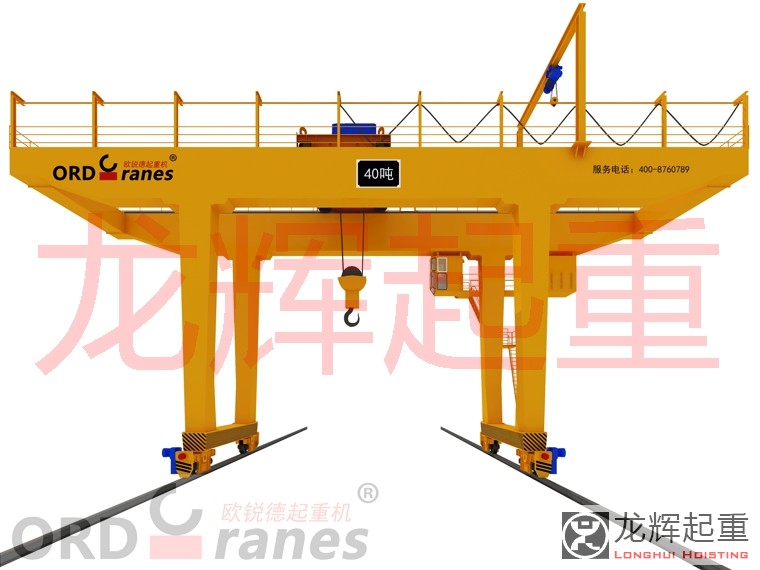

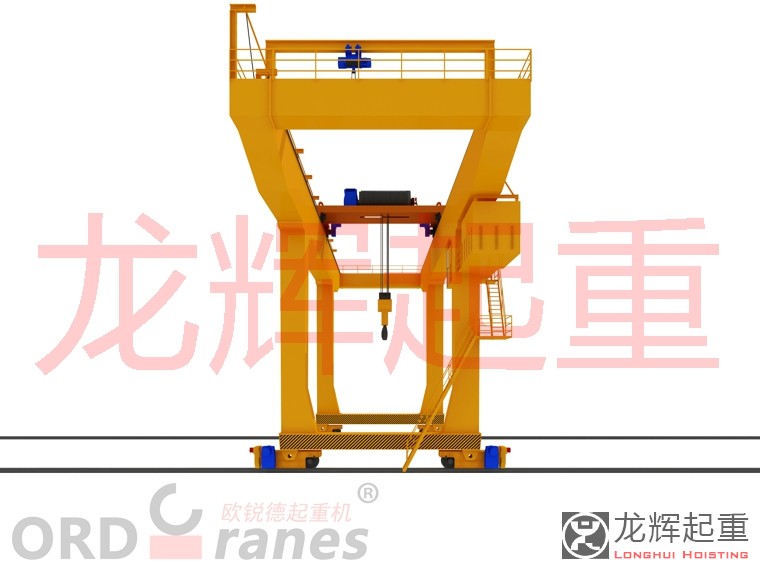

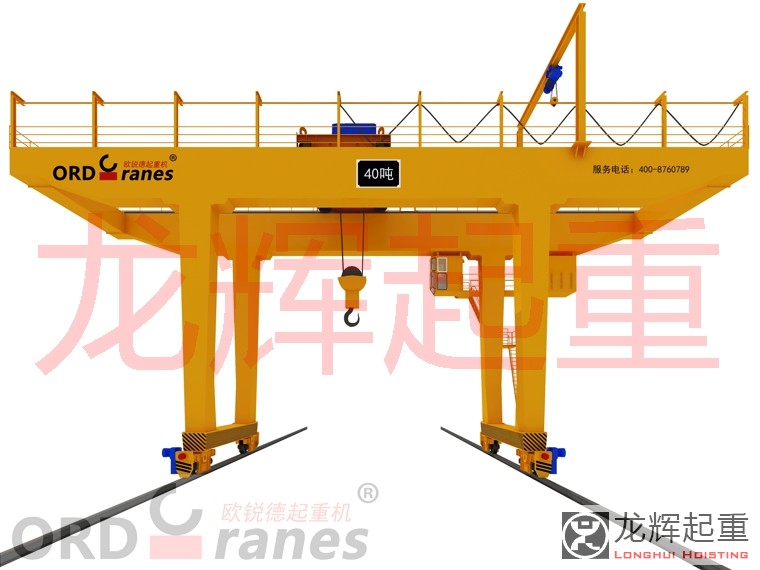

�b���bж������������ The track container gantry crane ��abbreviated for track lift�� ��the rubber tyred container gantry crane (abbreviated for tyred lift). For the loading and unloading work in Chinese container ports, we usually choose the coastal container crane and the tyred lift (which is the first choice for the rear yard). The track lift was only used some yards for it was much fallen behind the present port machinery requirements, such as work level, electric control system, handing system, so it can not meet the requirements of container loading and unloading in modern ports. ܉�E���c݆̥���Č�(du��)�� Comparison between track lift and tyred lift 2.1 ���γ߶� ��݆̥�ij��d����������C(j��)��ƫ���Ɇ�(w��n)�ļs����������ڬF(xi��n)�ڗl��������݆̥�������ͳ߶��Ѳ�̫Ҳ�S���д�Ĵ��ƣ�ͨ����������Խ23��47

m��6�м��b���1�l܇���������Ѹ߲���Խ18. 2 m����5�^(gu��)6��������܉�E���Ŀ����_(d��)40

m��12�м��b�䣩���������ֻ��ш�(ch��ng)���d���ܝM�㣬�Ѹ߿ɳ�Խ7һ8����������܉�E��߀�������졣���܉�E���Ĉ�(ch��ng)��������Ҫ����݆̥������� For the limits of carrying capacity of tires, machine deviation,etc, the outline dimension of tyred lift can not be improved at present , the general parameters are��span�Q23.4m,( 6 containers plus 1lane), pile height��18.2(5-6). But the span of track lift can be above 40 meters(12containers), and pile height can be above 7-8 layers, and extension included, so the place utilization rate of track lift is much higher that of tyred lift. 2.2 ���X���� �F(xi��n)��������܉���������ٶȵȼ��܅���(sh��)��һ������2�N�O(sh��)�����ُ(g��u)��(b��o)�r(ji��)���������܉�E���Ե��������P(gu��n)�ڴa�^��Ո(q��ng)��܉�E�����x���^��܇݆�������c�F(xi��n)��ͨ����8��(g��)܇݆��݆̥����ȣ�݆����Щ�����܉�E���轨����׃�վ����O(sh��)��|������܉�E�ȣ��ш�(ch��ng)������Y�^��. For combing the technological parameters together, such as: gauges,speeds, the bid prices for these two kinds of cranes are more or less. According to requests from the port, the track lift can select more wheels ,compared with the tyred lift( usually 8 tyres), it has less wheel pressure. But the track lift needs supported transformer substation,cable laying,track, so the yard construction cost is comparatively higher. ���\(y��n)�D(zhu��n)�������܉�E��ͨ�^(gu��)늾W(w��ng)ֱ��������������݆̥���t������Ԏ����͙C(j��)�l(f��)������������Y(ji��)һ�ӄ�(d��ng)���������M(f��i)һ�������Ġ�r�����ֱ�ӏ�늾W(w��ng)��늱����аl(f��)늱��X������e�ģ�

݆̥��̎�ڵȴ���r�r(sh��)���������͙C(j��)߀��p�IJ����~������ϣ���܉�E���������M�����͕r(sh��)߀�в�������������늾W(w��ng)����������܉�E�����ܺ��@��Ҫ�͵ö࣬���\(y��n)�D(zhu��n)���X��

���^��(y��u)��(sh��)���� During operation, the power of the track lift is from the electricity grid, but the tyred lift needs an attached diesel electrical machine, so for the same action and power consumption, the cost of power from grid is much less than that supplied by oneself. While the tyred lift is on standby, the diesel electrical machine is still consuming extra diesel, but the track lift could repay some power to the grid while its lifting mechanisms are lowing. So the energy consumption of track lift is much lower and thus a good advantage in operation cost. ݆̥���x�ò��͙C(j��)�������������M(j��n)�ڵIJ��͙C(j��)�MҲ���^�ߵ�ë���ʣ�߀���r(sh��)�M(j��n)�б��o(h��)�ʹ����������С�����������܉�E���x�õ�����|��Ͳ��늣��M(j��n)����|��Ͳ�S��ͨ���܉�_����3 -5��o(w��)ë���\(y��n)�D(zhu��n)������܉�E���x�����܇݆�������������܉�_�������C(j��)һ�������݆̥����݆̥�趨�r(sh��)��Q�� The tyred lift selects diesel machinery which needs regular maintenance, reparation,overhaul, and there always be somethings wrong with it even for imported ones. The track lift selects cable drum for power supply which can work without trouble for 3-5years. The track lift selects steel wheel whose life is as long as the whole machinery, while the tyres need replacement if necessary. 2.3 ���I(y��)���� ��?y��n)�܉�E�ͼ��b�䷽λ����(du��)�̶�������܉�E����(ji��)ʡ�ˌ�(du��)��r(sh��)�g�������Ը�����݆̥���Ĵ�܇������ƫ�������܇���ͼ��b�䷽λ�o(w��)���̶����������н�(j��ng)�v��˾�C(j��)�����M(j��n)�е��߷��D(zhu��n)�ʹ�܇�mƫ��(d��ng)��������Ӱ����I(y��)���ʡ��F(xi��n)�ڛ](m��i)�гʬF(xi��n)�����õ�����(d��ng)�mƫ�wϵ������ For the positions of the track and containers are comparatively fixed, the track lift saves time in operation on containers with a higher work efficiency. There always be deviation for the tyred lift trolley, and the positions of track and containers are not fixed, all above need an experienced driver operate reverse and correction, thus affects whole work efficiency. There has not been very usually automatic correction system yet. 2.4 ����(d��ng)�ٿغʹa�^�k���wϵ Automatic operation and port handing system ��?y��n)���܉�E���\(y��n)�D(zhu��n)�����܉�E���^��(ji��n)��������C(j��)��r�ıO(ji��n)�y(c��)��λ������ɶ�N����(d��ng)���������(d��ng)�ٿأ��M(j��n)������������늿��wϵ�M(j��n)һ���_(k��i)չ�Ġ�r���������(l��i)܉�E����Ҳ�S�_(k��i)չ

�鲻�����{�T�ğo(w��)�˶ш�(ch��ng)�wϵ�����݆̥�������C(j��)��r��λ�D�y���y���������(d��ng)�ٿ����܉�E�����x�ù��w�c�a�^�п���ͨӍ�����V������������ɔ_���ܺ���������F(xi��n)�ڼ���Ҳ��

�^�Ͼ������݆̥��ֻ���x�ßo(w��)��ͨӍ���������խ�������ɔ_���ܲ�������F(xi��n)�ڴ�ֻ�܆���Ӽ{һЩ��λ�Ⱥ�(ji��n)����Ϣ��߀�y����Y(ji��)��߅���b�����ؙC(j��)�ǘӵ�RCMS�wϵ�����

�⣬�o(w��)��ͨӍ߀���ڱض��Ă�ݔ������� ���_(t��i)܉�E����(du��)��(y��ng)�ļ��b���ܶ��^�Ѹ�Ҳ�^����������^�ߵ��k��ˮƽ���Ա����l�l������� For operation on tracks, the track lift can briefly finish position monitoring, active operation, semi-active operation with high efficiency. With the development of electric control system, there would be no man yard system for track lift, the optical fiber can be used between the track lift and the control room for communication with wild bandwidth and anti-interference quality, while the tyred lift can only select wireless communication with narrow bandwidth and worse anti-interference quality for only single direction brief information transmission, so it is hard to install RCMS system used in container cranes. Otherwise there is blind area for wireless communication. For a single track lift , the container density is large, the pile height is higher, thus a higher handing level without turning over is needed. 2.5 ��ȫ�Ժͭh(hu��n)�����o(h��) ܉�E����܉�E���\(y��n)�D(zhu��n)������(hu��)��ƫ�����������݆̥���\(y��n)�ò��͙C(j��)�l(f��)������l(f��)���^����Ⱦ����������� �mȻ�����Ɇ�(w��n)�F(xi��n)�ڌ�(du��)�ۿڵ�Ӱ�߀���@����������ľ��h(yu��n)��(l��i)�����@Щ�Ɇ�(w��n)���ò��м�(x��)˼������ 2.5 saety and environment protection The track lift travels on tracks without devition while the tyred lift would make more pollution and noise consuming diesel for power. Although all infulueances caused by these problems are not necessaryly worth of attention,they do deserve careful consideration in future. 2.6 �D(zhu��n)��(ch��ng)�`���� ܉�E���D(zhu��n)��(ch��ng)�D�y���mȻ�F(xi��n)�ڴ��܉�E�����ܶ���(du��)���Ͼ�����������I(y��)���Բ��ܒ߳��l(f��)��ë����Ҳ�S������������һ�l܉�E������Ҫ�b��2�_(t��i)܉�E�����e������mȻ�܉���

�ш�(ch��ng)�����������M���������صג߳���ͬһ�l܉�E�ϰl(f��)��ͻ�l(f��)�¼���������_(t��i)܉�E��һ�����I(y��)�Ġ�r�������(j��)��(gu��)��Ľ�(j��ng)�v��ͨ����ͬһ܉�E�϶�Ҫ�b����_(t��i)܉�E�������

݆̥����?y��n)��܉��l�l�D(zhu��n)��(ch��ng)���͛](m��i)���@������Ɇ�(w��n)����������������P(gu��n)��ijЩ܉�E�^�̶��电(sh��)�^��Ķш�(ch��ng)������܉�E���������m������� 2.6 Transition flexibility It is hard for track lift to operate transition easily even of comparitively advanced technology and for the uncertainty of something wrong in operation ,there should be at least 2 spare track lifts ready for use in case of need.Else although there could be alteration to stack yard organization,it is still necessary for some track lifts working together in case of some unavoidable accidents.For experiences abroad, there usually be some track lifts working on the same track.While the tyred lift can operate transition easily thus no problems mentioned above for it.So the track lift is not suitable in conditions of short track and more transitions. ��������(qi��ng)�D(zhu��n)��(ch��ng)�`���ԣ�܉�E��Ҳ���ЎN�D(zhu��n)��(ch��ng)Ӌ(j��)��������@Ҳ��܉�E����ӑ��һ��(g��)�����������e���������(gu��)��Ҳ���ڴ����܉�E�������(n��i)���b��һС���܉�E����Ӌ(j��)�������� For improving the transition flexibility,there could be some transition plans for track lift thus a discussion direction.There be a foreign plan namely to set a smaller track lift within the track gauge of a big one. ԓ�C(j��)��������ɫ�� ��1��32 m܉��������ɷ���8�м��b���2�l܇����� ��2������^�������(j��ng)������Ӌ(j��)��C(j��)ģ�M���I(y��)��r���F(xi��n)�x�õă�߅�����ȵĽ��ٽY(ji��)��(g��u)�����Ќ�(du��)�Ⱥõ�ƽ������� ��3���x������ʽС܇�(q��)��(d��ng)��������С܇���(q��)��(d��ng)늄�(d��ng)�C(j��)�����p��������Ƅ�(d��ng)���Ⱦ����b��С܇���������ͨ�^(gu��)�f(w��n)��(ji��)����(d��ng)��(l��i)�(q��)��(d��ng)ǰ��4��(g��)܇݆���x���@�N�(q��)��(d��ng)�����܉����p���o(h��)��Q䓽z�K�����I(y��)�������� ��4��С܇܉�E�x���M(j��n)�ڵ�A65��܉����̤�挒�����߶ȵ����������(c��)���Ժ���������ܷdz��õؽ�����?y��n)�С܇ƫб��܉�l(f��)���Ă�(c��)���������� ��5����܇�\(y��n)�D(zhu��n)�ٶ��^�������x��늄�(d��ng)�C(j��)����p���䡢�Ƅ�(d��ng)������һ�(q��)��(d��ng)�M����������M�����p����(d��ng)�h(hu��n)��(ji��)���Ķ����p�����\(y��n)�D(zhu��n)�е�ĥ�p����������܇݆���e�O(sh��)Ӌ(j��)�ģ�������̤�挒�Ⱥ�݆����(qi��ng)��������ԑ�(y��ng)��(du��)Ҳ�S�ʬF(xi��n)�Ŀ�܉�Ɇ�(w��n)��� ��6���b���˙C(j��)е���u�wϵ���b������������ԭ��(l��i)��(ch��ng)����ͨ�õ�Һ��ʽ�p�u�wϵ����pС�˱��X�ͱ��o(h��)���I(y��)����� ��7���x���Ɍ��TPLC�ٿص���|��Ͳ���_����Ͳ�c��܇�\(y��n)�D(zhu��n)�ٶȵ�ͬ���������߀ͨ�^(gu��)�^(gu��)��|�ӕr(sh��)�p�ٵķ�����(l��i)�p����(du��)���|�ě_�������� ��8���x��AB��늚˾��ȫ׃�l��ͨ�{(di��o)���(q��)��(d��ng)�wϵ������_������ɿ��\(y��n)�D(zhu��n)��� Features of the crane: (1) Track gauge for 32m which capable of 8 containers and 2 lanes. (2)For larger span and after analysis and computer simulation of working conditions,a metal structure with rigid legs chosen now has a better balance quality. (3)Seletion of self-propelled driving method manely the driving motor,gearbox,brakes are all installed on the trolley frame, which drives the four wheels by the universal joint.This driving method can reduce the amount of work to protect and replace steel wire rope. (4) A65 short track imported is selected as trolley track ,with wider width,low height,good lateral rigidity,can afford the lateral force caused by trolley skew. (5) The crane tranverses in higher speed, adopted with 3(motor,gearbox,brakes)in 1 driving mechanisums,be trying to reduce transmission process, thus reducing wear and noise in high speed tranversing.The wheels are specially designed with enhanced width and rim strength to deal skew. (6) The hydraulic anti-rolling system on bridge has been replaced by mechanical anti-shake system to reduce the costs and protection work amount. (7)The cable drums contrilled by dedicated PLC are selected to the synchronization tranversing speed of drums and crane. Cable pit deceleration is also used to reduce the impact to cables. (8)Full frequency communication speed drive system by AB company is applied to realise reliable tranversing. Shandong Longhui Hoisting Machinery CO.,LTD

Website: http://www.lhqzj.com

E-mail: longhui@188.com

|